PCBs for automotive lightings

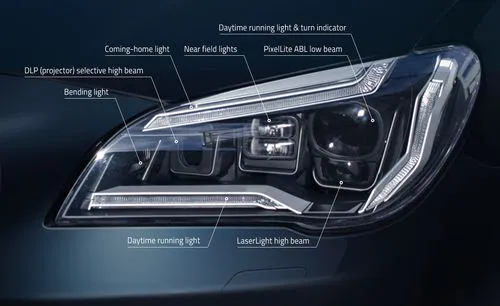

Printed circuit boards (PCBs) are commonly used in automotive lighting systems, including headlights, taillights, and interior lighting. As the automotive industry shifts towards electric and hybrid vehicles, there is a growing demand for more advanced lighting systems that use LEDs and other energy-efficient technologies.

To meet the requirements of automotive lighting applications, PCBs must be designed and manufactured with high-quality materials and advanced manufacturing processes. They must also be able to withstand the high temperatures, vibrations, and moisture that are common in automotive applications.

In addition, there is a growing trend towards integrating lighting systems with other vehicle electronics, such as sensors and control systems. This requires PCBs that are able to communicate with other electronic components and systems, and that can handle the increased data processing requirements.

To stay competitive in the automotive lighting market, PCB manufacturers must stay up-to-date with the latest trends and developments in lighting technology. This includes advances in LED technology, as well as the development of new materials and manufacturing processes that can improve the performance and reliability of PCBs in automotive lighting applications.

Overall, the demand for high-quality, reliable, and advanced PCBs in automotive lighting applications is expected to continue to grow as the automotive industry shifts towards electric and hybrid vehicles, and as new lighting technologies continue to be developed.